Necessary Tools and Strategies for Effective Lead Offense Cleanup

Addressing lead violations properly demands a detailed strategy that blends the right devices with critical techniques. The primary step entails gearing up workers with Personal Safety Equipment (PPE) to secure their health. Simultaneously, using specialized cleaning tools, such as HEPA vacuums and lead-specific cleaner, is essential for comprehensive impurity elimination. Efficient containment approaches, including plastic sheeting and unfavorable atmospheric pressure systems, are important to prevent the spread of unsafe products. Safe disposal practices and strict adherence to regulative guidelines make sure liable handling of harmful waste. Yet what are the nuanced approaches that genuinely make a difference?

Individual Protective Tools

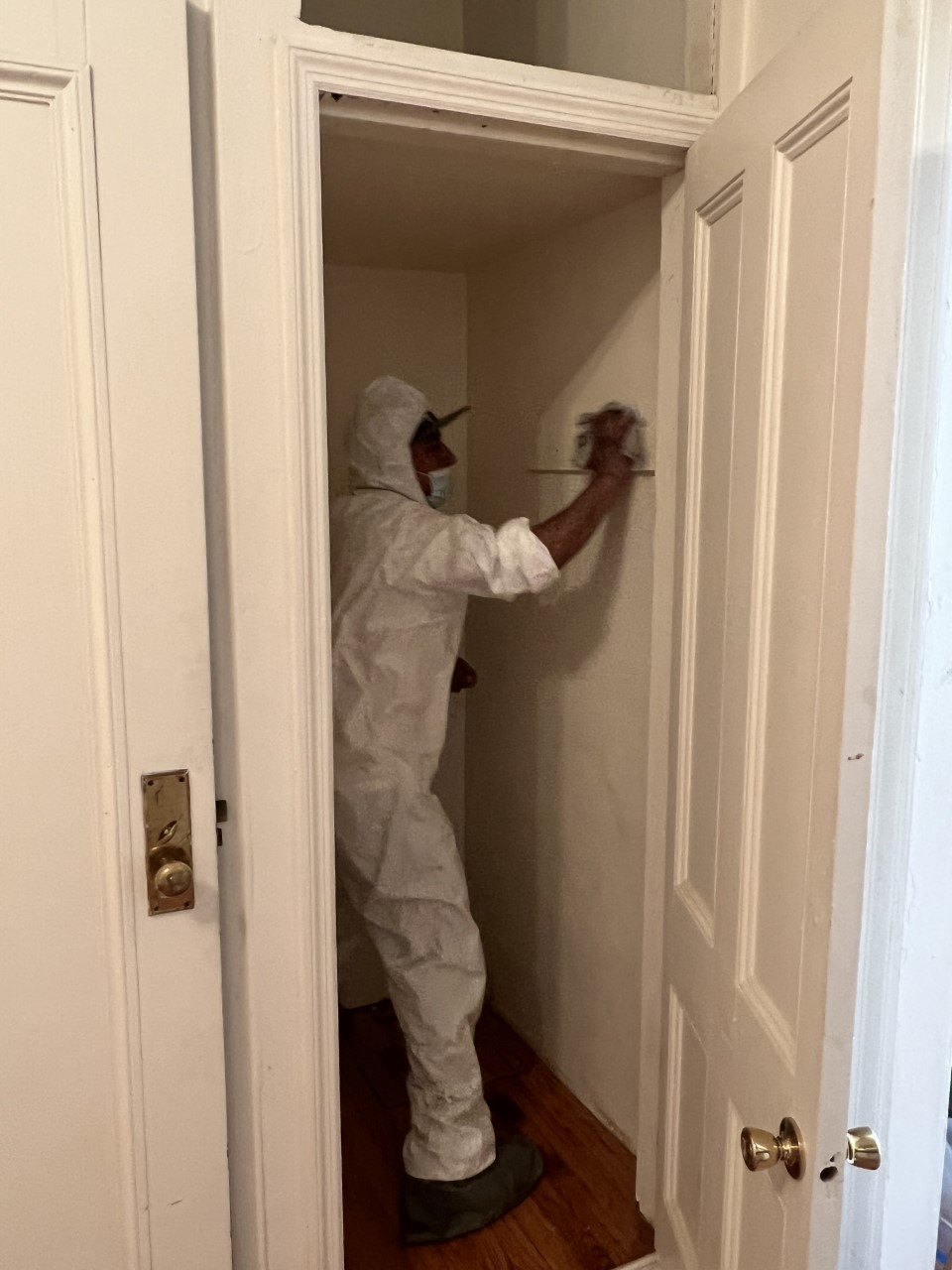

Individual protective tools (PPE) is a crucial element in the reliable monitoring of lead contamination clean-up. PPE offers as a crucial obstacle, safeguarding workers from the harmful results of lead direct exposure, which can cause extreme health repercussions. The vital PPE for lead clean-up consists of respirators, safety garments, handwear covers, and eye security. Each kind of tools is especially made to minimize various threats related to lead particles and dirt.

Respirators, particularly those geared up with HEPA filters, are essential for filtering system air-borne lead particles, protecting against inhalation. Safety garments, including coveralls and non reusable suits, protects against lead dust from sticking to workers' garments, reducing the danger of secondary contamination.

Furthermore, strenuous training on the appropriate use and maintenance of PPE is essential. Workers must be informed on donning and doffing procedures to stay clear of contamination. Routine examinations and replacements of PPE elements are necessary to preserve their safety capabilities, making sure a safe and compliant cleaning operation.

Specialized Clean-up Devices

Another necessary device is the wet/dry vacuum cleaner, which can successfully clean up both dust and liquid pollutants. These vacuums frequently feature HEPA filters to offer an added layer of safety. Wet cleans or tack cloths are likewise vital for surface cleaning; they are particularly made to capture and hold lead bits, lowering the risk of spreading contamination.

For more stubborn down payments, specialized lead-removal cleaner are required. These agents are developed to damage down lead fragments, making them easier to remove. Scrub brushes with durable bristles can help in this procedure, specifically on harsh surface areas where lead dust tends to adhere a lot more highly.

Additionally, encapsulants are utilized to seal lead-contaminated surfaces, protecting against the launch of lead dust. These specialized paints and finishes are made to follow different substratums, giving a long-term remedy for lead containment.

Efficient Control Approaches

Effective control techniques are important in mitigating the spread of lead contamination throughout clean-up activities. Applying robust control methods makes sure that lead particles do not move to untouched areas, therefore shielding both workers and the setting (DOH & HPD Lead Violation the original source Removal NYC).

To enhance control, encapsulants can be applied to surfaces that are not being gotten rid of or disrupted. These specialized coatings bind lead dirt, minimizing its availability for resuspension. In addition, all personnel have to use appropriate Individual Protective Tools (PPE), including respirators and non reusable suits, to avoid contamination spread.

Safe Disposal Practices

Making sure secure disposal practices is an important part in the management of lead contamination clean-up. Appropriate disposal mitigates the risk of lead coming back reference the atmosphere and threatening public health and wellness (DOH & HPD Lead Violation Removal NYC).

Moving lead waste requires adherence to strict guidelines. Utilizing accredited unsafe waste carriers ensures that the materials are dealt with properly. Paperwork, including materializes outlining the type and quantity of waste, must go along with deliveries to track the waste from the site of origin to its final disposal destination.

Designated dangerous waste disposal facilities are geared up to manage lead-contaminated products securely. These facilities typically utilize sophisticated techniques such as stabilization, solidification, or chemical treatment to neutralize the lead before disposal. Landfilling in specialized, lined areas that avoid leachate from polluting groundwater is a typical method for final disposal.

Routine training for workers included in lead waste disposal is vital to keep safety and security standards and stop accidental direct exposure. By sticking to these techniques, companies can significantly minimize the ecological and health and wellness impacts related to lead contamination.

Regulatory Conformity Tips

Following regulative compliance is extremely important in the effective execution of lead contamination clean-up. Comprehending and following government, state, and local guidelines guarantees not just the safety and wellness of people but additionally the legal and economic well-being of the cleaning company. The Epa (EPA) establishes rigorous requirements, such as the Lead Restoration, Fixing, and Paint (RRP) Rule, which mandates appropriate accreditation and training for service providers handling lead-based tasks.

Compliance starts with a comprehensive evaluation of applicable laws and guidelines. Organizations must remain upgraded on any kind of legislative changes, which can be assisted in via normal training sessions and subscribing to industry updates. Documentation is another vital conformity facet; keeping thorough documents of all tasks, consisting of examination records, staff member training logs, and disposal manifests, is crucial.

Additionally, involving with certified lead examiners or run the risk of assessors guarantees that lead dangers are properly determined and alleviated. Companies need to implement using Personal Protective Equipment (PPE) and ensure that safety and security methods are purely adhered to. Clear communication with stakeholders, including employees, customers, and regulative bodies, will certainly promote a society of compliance and responsibility, inevitably adding to a safer and more reliable lead cleanup process.

Conclusion

Efficient lead offense clean-up requires the combination of specialized tools and strategic methodologies to ensure safety and security and efficiency. Making use of HEPA vacuums, specialized cleaning representatives, and efficient containment methods such as plastic sheeting and adverse atmospheric pressure systems is necessary. Individual protective tools (PPE) safeguards workers from direct exposure, while safe disposal techniques and stringent adherence to governing compliance are essential for responsibly taking care of view it contaminated materials. Jointly, these steps considerably mitigate health and wellness threats and contribute to a cleaner atmosphere.